Film Capacitors for Electromobility Applications

In times of e-mobility, the demand for reliable, durable and partly customer-specific film capacitors is constantly increasing. WIMA offers a wide range of components, from standard capacitors to components specially configured according to customer specifications. All capacitors are made in Germany and comply with the well-known WIMA quality standard.

Specific e-Mobility Applications

- Car and battery air conditioning

SMD MKP RFI - Electric drives

SMD-PET SMD-PEN MKP - Motor inverter

MKP 10 FKP 4 FKP 1 MKP Snubber DC-Link - On-bord chargers

MKP 10 FKP 4 FKP 1 MKP Snubber DC-Link - Wall chargers

MKP 10 FKP 4 FKP 1 MKP Snubber DC-Link - DC/DC converter

MKP 10 FKP 4 FKP 1 MKP Snubber DC-Link - EMC filter

MKP-X2 MKP-Y2 MKP-X1 R MKP 4F

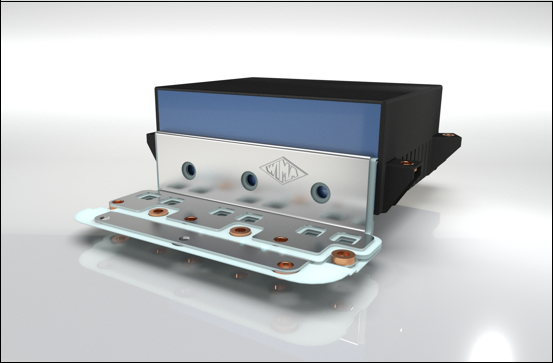

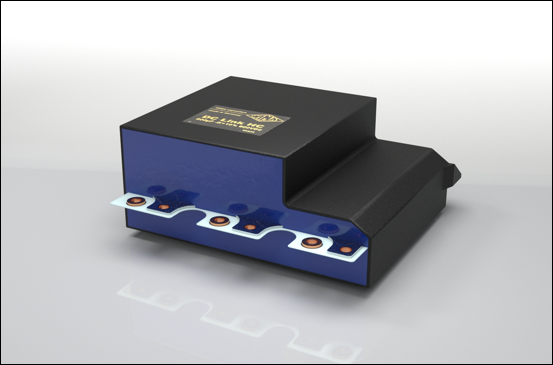

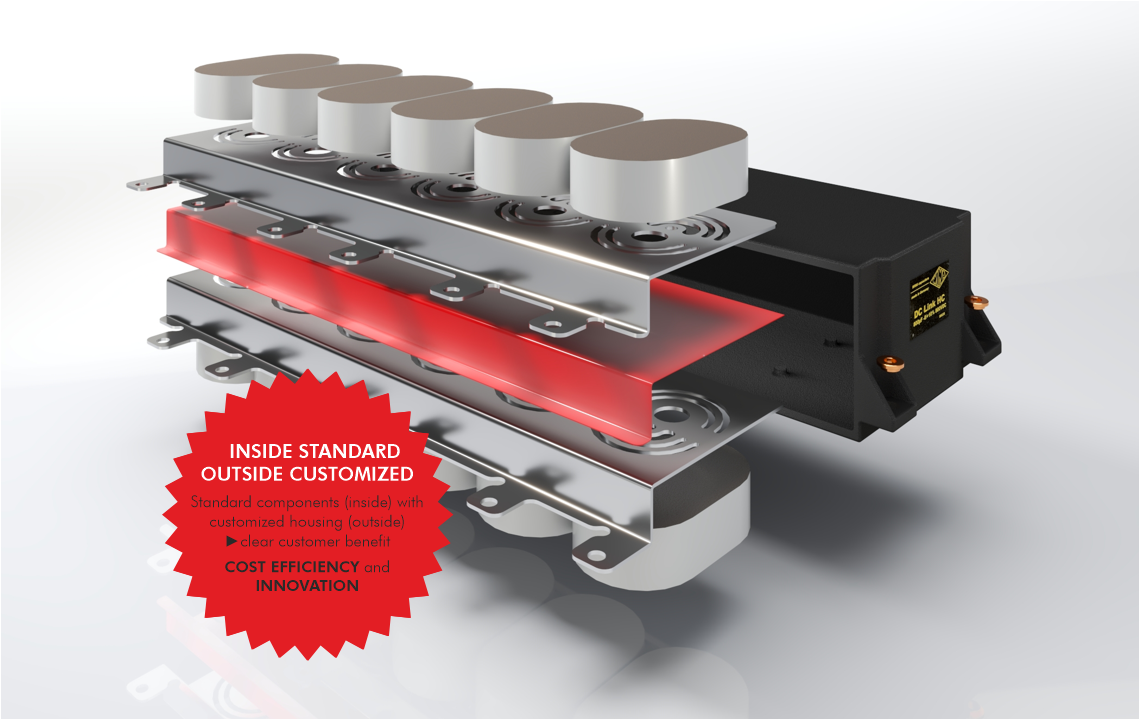

NEW: DC-Link Capacitors for SiC-Power Semiconductors

WIMA Low-Inductance (LI) DC-LINK capacitors are characterized by a flat, space-saving design with particularly low self-inductance. They are therefore particularly suitable for applications in combination with silicon-based SiC power semiconductors.

Advantages

- The LI configuration with a flat, space-saving design is available for all types and contact configurations

- Existing capacitor designs can be easily substituted with LI capacitors

- The LI design has no restrictions regarding the energy density per volume compared to previous DC link configurations

- The WIMA Single Side Cooling (SSC) achieves ideal heat dissipation with one-sided (water) cooling systems

- The LI design is available in 2- and 3-voltage level configurations.

Properties

- Low leakage inductance of <10 nH in almost any capacitor configuration

- Significant resonance point shift in high frequency ranges compared to conventional designs

- Optional: ESR optimized design and applicantion temperatures up to 125° C on request.

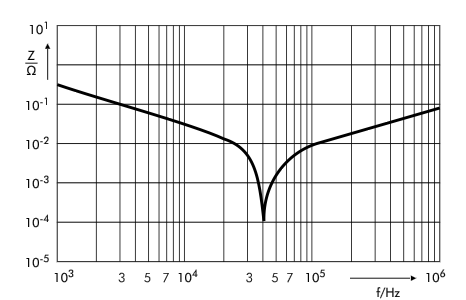

Impedance Change with Frequency for Reference Design

|

Cr = 500 µF ±10% ESR = 0.46 mΩ at 1kHz fR ~42.5 kHz -> ESL ~30nH |

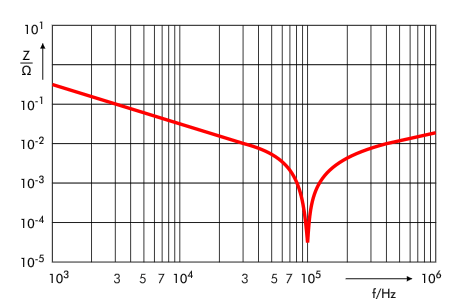

Impedance Change with Frequency for LI Design

|

Cr = 500 µF ±10% ESR = 0.4 mΩ at 1kHz fR ~100 kHz -> ESL ~5nH |

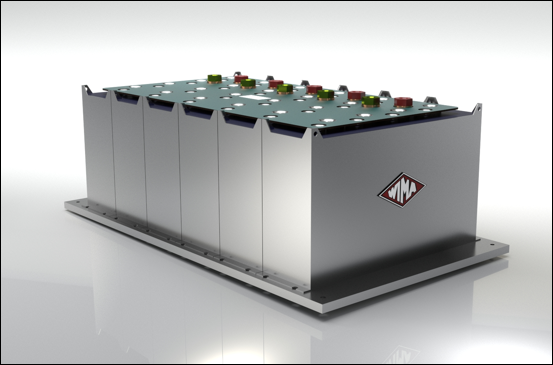

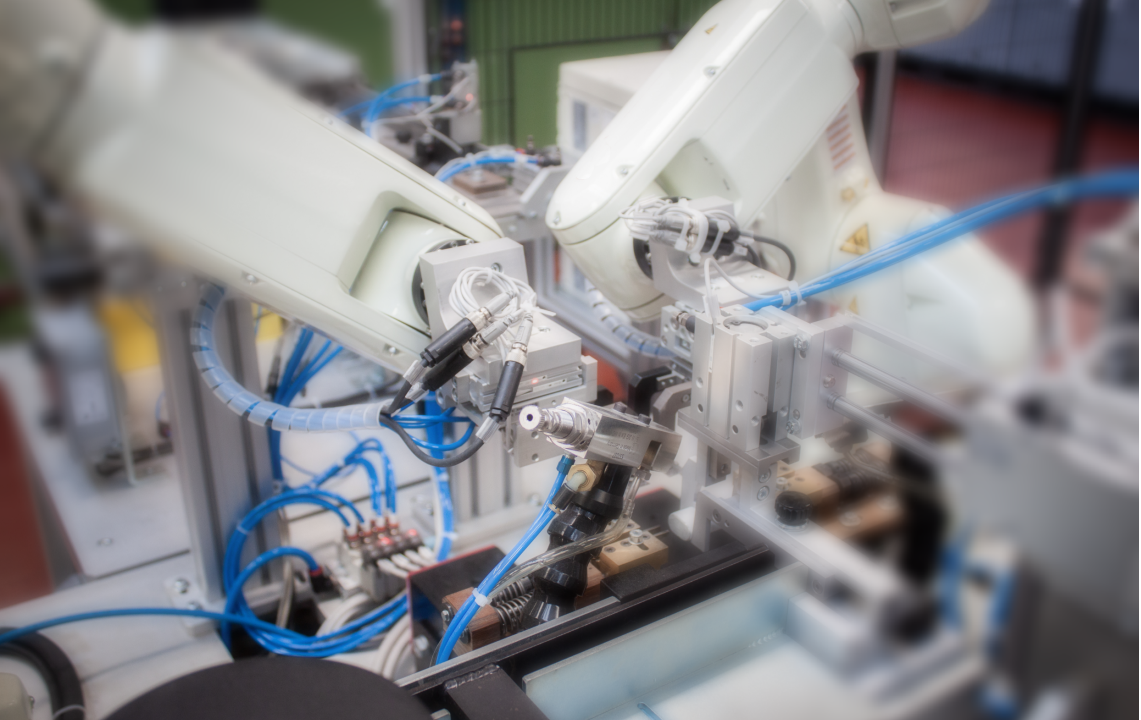

NEW: Robot Manufacturing of WIMA Capacitors

In an effort to improve production processes in terms of product quality and cost efficiency, WIMA is increasingly converting to state-of-the-art robot technology. This saves time and resources and also increases productivity in our capacitor production with regard to large-volume needs of our customers.

Advantages

- Automated production of all common WIMA DC-LINK capacitors with tab connections

- Assambly from the winding element to the finished capacitor in one process line

- Increase in efficiency due to shorter throughput times

- High quality due to precise robot control

- Optimized production process for medium an large series.

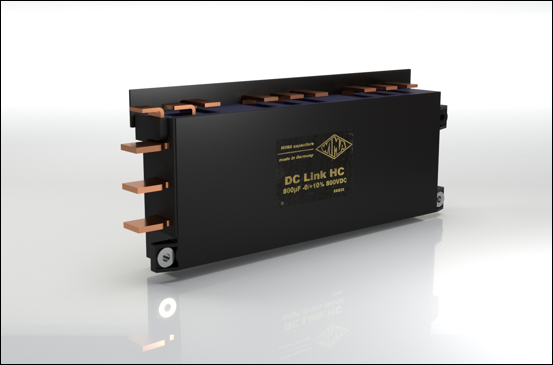

Examples for customized solutions