SMD-PET

Recommendation for Processing and Application of SMD Capacitors

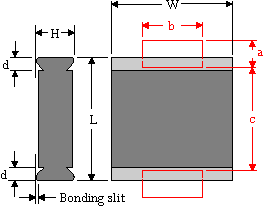

Layout Form

The components can generally be positioned on the carrier material as desired. In order to prevent soldering shadows or ensure regular temperature distribution, extreme concentration of the components should be avoided. In practice, it has proven best to keep a minimum distance of the soldering surfaces between two WIMA SMDs of twice the height of the components.As a basic principle for wave soldering, alignment of the soldering surfaces in accordance with the transport direction of the printed circuit board through the soldering wave is recommended.

Solder Pad Recommendation

| Size code | L ±0.3 | W ±0.3 | d | a min. | b min. | c max. |

| 1812 2220 2824 4030 5040 6054 |

4.8 5.7 7.2 10.2 12.7 15.3 |

3.3 5.1 6.1 7.6 10.2 13.7 |

0.5 0.5 0.5 0.5 0.7 0.7 |

1.2 1.2 1.2 2.5 2.5 2.5 |

3.5 4 4 6 6 6 |

3.5 4.5 6.5 9 11.5 14 |

Processing

The processing of SMD components- assembling

- soldering

- electrical final inspection / calibrating

must be regarded as a complete process. The soldering of the printed circuit board, for example, can constitute considerable stress on all the electronic components. The manufacturer's instructions on the processing of the components are mandatory.

Soldering process

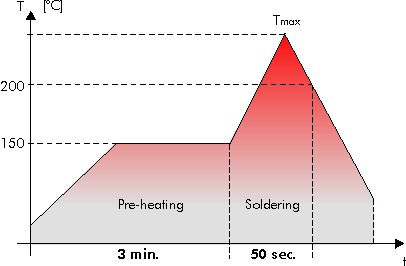

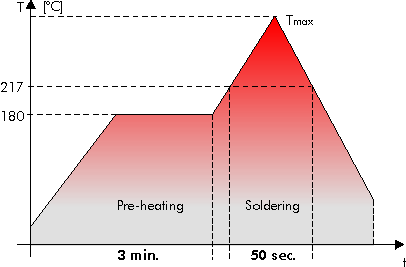

Temperature/time graph for the permissible processing temperature of the WIMA SMD film capacitors for typical convection soldering processes.

| SMD-PET | |

| Size code | Tmax. |

| 1812 2220 2824 4030 5040 6054 |

220°C 230°C 230°C 230°C 240°C 250°C |

| SMD-PEN | |

| Size code | Tmax. |

| 1812 2220 2824 |

250°C 250°C 250°C |

| SMD-PPS | |

| Size code | Tmax. |

| 1812 2220 2824 4030 5040 6054 |

250°C 250°C 250°C 250°C 250°C 250°C |

Due to versatile procedures exact processing parameters for re-flow soldering processes cannot be specified. The graph depicted is to be understood as a recommendation to help establishing a suitable soldering profile fulfilling the requirements in practice at the user.

During processing a max. temperature of T=210° C inside the component should not be exceeded. Due to the differing heat absorption the length of the soldering process should be kept as short as possible for smaller size codes.

SMD Handsoldering

WIMA SMD capacitors with plastic film dielectric are generally suitable for hand-soldering with a soldering iron where, however, similar to automated soldering processes, a certain duration and temperature should not be exceeded. These parameters are dependent on the physical size of the components and the relevant heat absorption involved.

| Size code | Temperature °C/°F | Time duration |

| 1812 2220 2824 4030 5040 6054 |

250/482 250/482 260/500 260/500 260/500 260/500 |

2 sec plate 1 / 5 sec off / 2 sec plate 2 3 sec plate 1 / 5 sec off / 3 sec plate 2 3 sec plate 1 / 5 sec off / 3 sec plate 2 5 sec plate 1 / 5 sec off / 5 sec plate 2 5 sec plate 1 / 5 sec off / 5 sec plate 2 5 sec plate 1 / 5 sec off / 5 sec plate 2 |

The above data are to be regarded as guideline values and should serve to avoid damage to the dielectric caused by excessive heat during the soldering process. The soldering quality depends on the tool used and on the skill and experience of the person with the soldering iron in hand.

Solder Paste

To achieve reliable soldering results one of the following solder alloys have from case to case proven being workable:Lead-free solder paste

Sn - Bi

Sn - Zn (Bi)

Sn - Ag - Cu (suitable for SMD-PET 5040/6054 and SMD-PPS)

Solder paste with lead

Sn - Pb - Ag (Sn60-Pb40-A, Sn63-Pb37-A)

Washing

WIMA SMD components with plastic encapsulation - like all other components of similar construction irrespective of the make - cannot be regarded as hermetically sealed. Due to today’s common washing substances, e. g. on aqueous basis instead of the formerly used halogenated hydrocarbons, with enhanced washing efficiency it became obvious that assembled SMD capacitors may show an impermissibly high deviation of the electrical parameters after a corresponding washing process. Hence it is recommended to refrain from applying industrial washing processes for WIMA SMD capacitors in order to avoid possible damages.

Initial Operation / Calibration of the Device

Due to the stress which the components are subjected to during processing, reversible parameter changes occur in almost all electronic components. The capacitance recovery accuracy to be expected with careful processing is within a scope of |ΔC/C| < 5%For the initial operation of the device a minimum storage time of t > 24 hours is to be taken into account. With calibrated devices or when the application is largely dependent on capacitance it is advisable to prolong the storage time to t > 10 days In this way ageing effects of the capacitor structure can be anticipated. Parameter changes due to processing are not to be expected after this period of time.

Humidity Protection Bags

Taped WIMA SMD capacitors are shipped in humidity protection bags according to JEDEC standard (ESD/EMI-shield / water-vapour proof). Under controlled conditions the components can be stored two years and more in the originally sealed bag. Opened packing units should immediately be used up for processing. If storage is necessary the opened packing units should be stored air-tight in the original plastic bag.

Reliability

Taking account of the manufacturer's guidelines and compatible processing, the WIMA SMD stand out for the same high quality and reliability as the analogous through-hole WIMA series. The technology of metallized film capacitors used e.g. in WIMA SMD achieves the best values for all fields of application. The expected value is about:λ0 < 2 fit

Furthermore the production of all WIMA components is subject to the regulations laid down by ISO 9001:2015 as well as the guidelines for component specifications set out by IEC quality assessment system (IECQ) for electronic components.

Electrical Characteristics and Fields of Application

Basically the WIMA SMD series have the same electrical characteristics as the analogous through-hole WIMA capacitors. Apart from the advantages shown in the diagrams of the electrical parameters in comparison with X7R ceramic and tantalum capacitors, WIMA SMD capacitors have a number of other outstanding qualities compared to ceramic or tantalum dielectrics:- favourable pulse rise time

- low ESR

- low dielectric absorption

- available in high voltage series

- large capacitance spectrum

- stand up to high mechanical stress

- good long-term stability

- measuring techniques

- oscillator circuits

- differentiating and integrating circuits

- A/D or D/A transformers

- sample and hold circuits

- automotive electronics